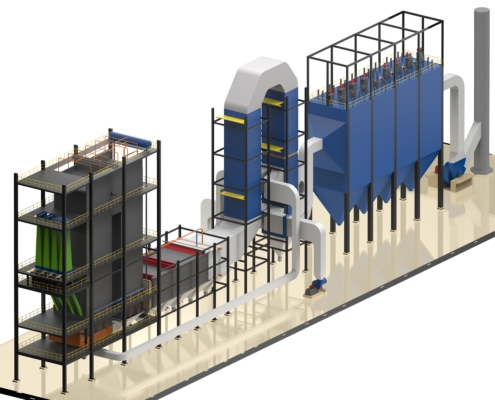

Uttamenergy’s mainstream proven product, with hundreds of references and engineering designs perfected over the last 40 years. This boiler has demonstrated its performance and dependability using fuels such as bagasse, rice husk, coal, and wood chips.

A bi-drum steam boiler layout guarantees dependability and flexibility for a wide range of operating pressures, as well as ease of maintenance. Traveling grate stokers provide excellent combustion with the seamless and trouble-free operation, and their increased heat release rates allow for smaller boiler designs. The drive for the grating can be either hydraulic or motor operated.

- Capacity range: 8 – 200 tph

- Maximum Pressure: 125 Barg

- Maximum Temperature: 540 °C

- Fuels: Bagasse, rice husk, wood chips, coal

Unique Features

- Response time to load changes is instantaneous.

- Compactness of combustor and boiler

- Fuel versatility using both biomass and fossil fuels

- Reduced stack losses as a result of decreased surplus air levels

- Ease of maintenance and operation

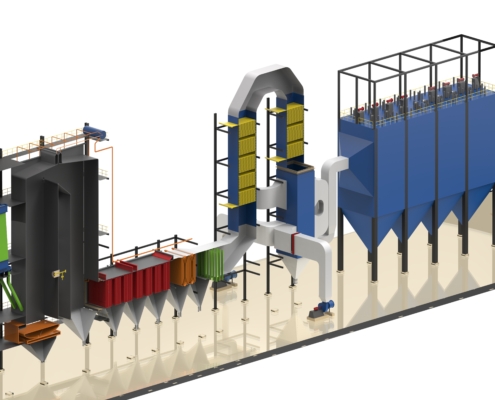

Uttamenergy created a unique one-pass design for difficult fuels such as empty fruit bunch, palm fibre, wood barks, and napier grass. These fuel types often have a greater alkali concentration, which causes fouling of boiler heat exchangers. The combustion room is large enough and has enough cooling surface to reduce the fouling potential of alkali salts in these fuels.

Reciprocating Servo Grate (RSG) is designed in-house and meticulously sized to suit steam boiler design. To promote staged and efficient burning, fuel is gravity supplied at one end of the grate. Because of this silent combustion, higher moisture fuels are burned more efficiently, with less fly ash carryover.

- Capacity range : 8 – 80 tph

- Maximum Pressure : 67 Barg

- Maximum Temperature : 480 °C

- Fuels : Palm waste, wood bark, Napier grass

Unique Features

- Capable of handling fibrous fuel and high moisture

- Boiler layout ideal for fouling-prone fuels

- Limits combustor fly ash carryover and lower fouling annoyance

- Develop heat transfer surfaces to compensate for fouling.

- Soot blowing is done automatically and effectively to boost boiler availability.

- Reduced unburned losses as a result of efficient combustion

- Ease of maintenance and operation

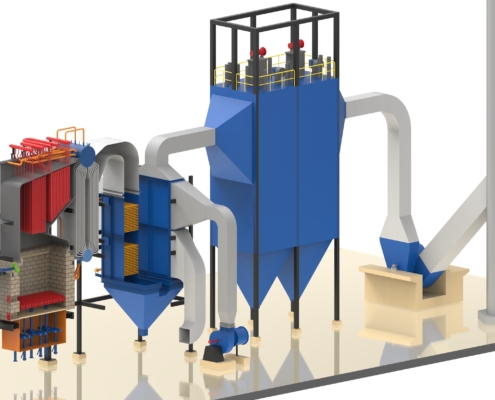

Uttamenergy designed an original tail-end incineration boiler design for firing distillery vinasse/slop effluent in conjunction with supplementary fuels such as bagasse, wood chips, rice husk, and coal. The careful design of the soot blower mechanism guarantees that boilers are more available. Traveling grate stokers are thought to provide greater flexibility in firing support fuels.

- Capacity range : 8 – 100 tph

- Maximum Pressure : 45 Barg

- Maximum Temperature : 400 °C

- Fuels : Vinasse, slop

Unique Features

- Capable of handling slop with concentrations ranging from 45 to 60 brix.

- Guaranteed boiler uptime/availability for up to 120 days.

- With unique waste spray-type soot blowers, boiler uptime/availability is guaranteed for up to 220 days.

- To compensate for fouling action, the tail end is designed with intricate heat transfer surfaces.

- Soot blowing is done automatically and effectively to boost boiler availability.

Coal-fired fluidised type boilers are the most effective technology for burning high ash fuels such as coal and rice husk. This combustion technology, when used with bi-drum type boilers, provides more capacity flexibility and smooth functioning of the boiler.

- Capacity range : 6 – 200 tph

- Maximum Pressure : 125 Barg

- Maximum Temperature : 540 °C

- Fuels : Coal, rice husk

Unique Features

- Coal combustion efficiency using fluidized bed technology

- Response time to load changes is instantaneous.

- Compactness of combustor and boiler

- Reduced stack losses as a result of decreased surplus air levels

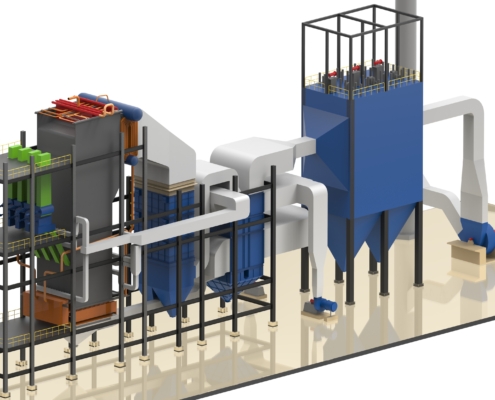

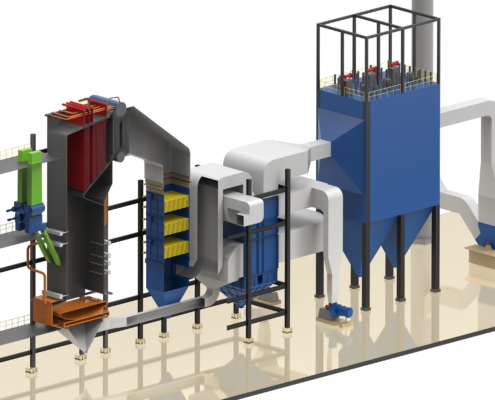

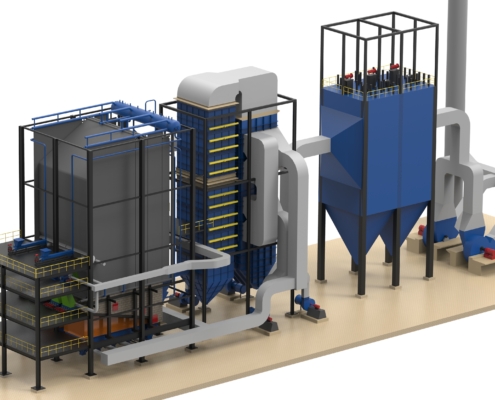

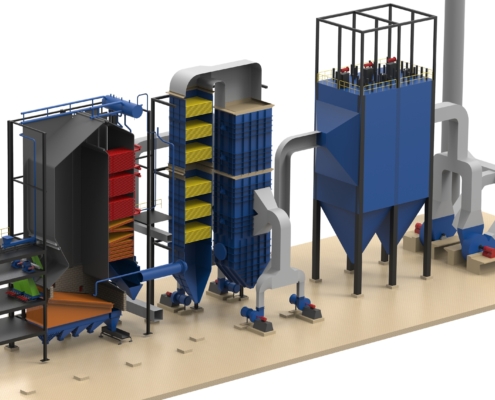

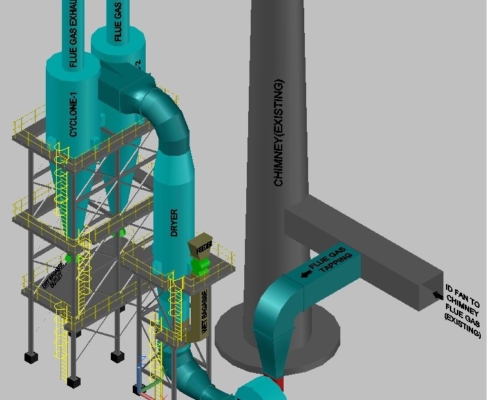

Bagasse dryers are in-house created unique equipment that uses waste flue gas energy dumped via the chimney to dry wet bagasse.

Flue gases from the boiler are driven through the dryer, with wet mill bagasse supplied at the bottom of the dryer through a rotating air lock feeder. Wet bagasse is transported upward with hot flue gas due to concurrent flow at a specified velocity based on Average Particle Retention Time (APRT). During this process, the moisture in the bagasse evaporates, and the dry bagasse is separated using high-efficiency cyclone separators.

This dry bagasse is continually expelled from the bottom of the cyclone(s) via air-lock valves for further processing in the boiler. There is enough automation, including differential pressure monitoring.

Unique Features

- Increase boiler efficiency to 77% or higher.

- Bagasse moisture reduction of up to 37% or less is possible.

- To avoid bagasse clogging, an online monitoring system is in place.

- Parts made of stainless steel in important locations for increased durability

- VFD-controlled booster fan for smoother performance in the face of temperature and moisture variations.