Efficient and Reliable Palm Waste / Napier Grass Fired Boilers – Made in India

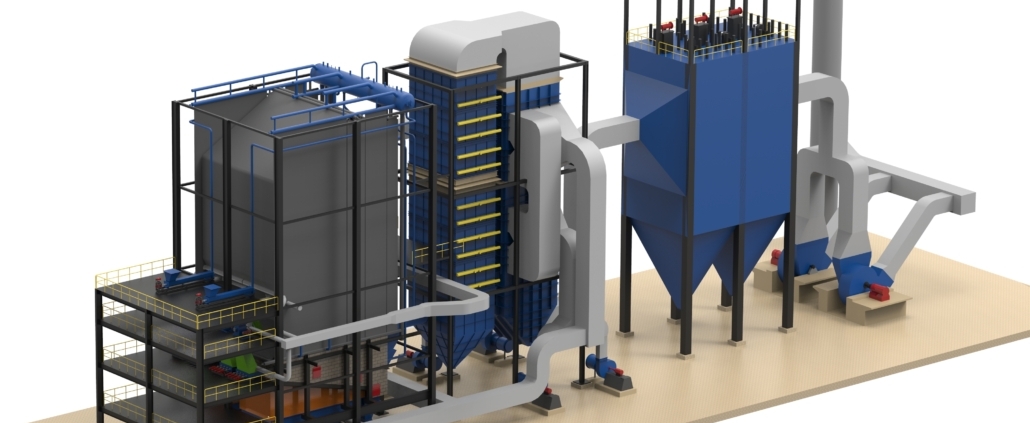

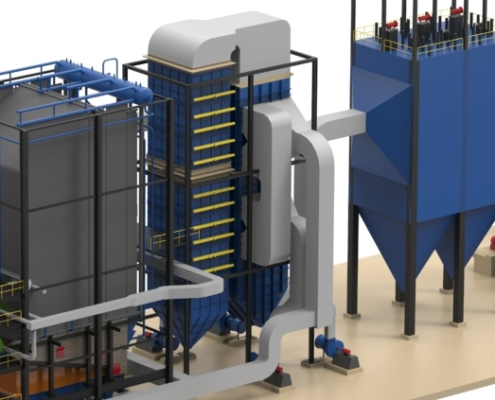

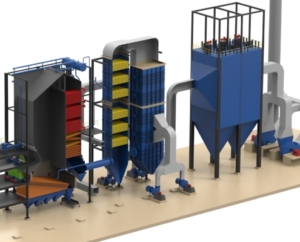

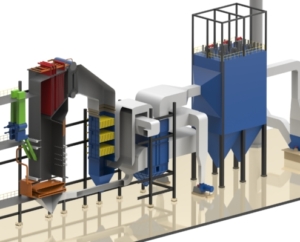

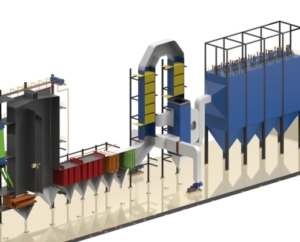

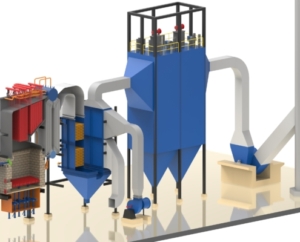

Palm waste / Napier grass fired boilers are unique single pass design developed by Uttamenergy for challenging fuels like empty fruit bunch, palm fiber, wood barks and napier grass. These fuel types typically have a higher alkali content which has a sticky nature resulting in fouling of boiler heat exchangers. The combustion room is spaciously sized with a sufficient cooling area to minimize fouling potential of alkali salts in these fuels.

As a trusted palm waste boiler manufacturer and Napier grass boiler manufacturer based in India, we recognize the significance of harnessing these biofuels effectively. Our boilers are specifically designed and optimized to efficiently burn palm waste and Napier grass, ensuring maximum energy extraction while minimizing environmental impact.

By investing in our palm waste boilers and Napier grass fired steam boilers, businesses can contribute to sustainable practices and reduce their carbon footprint. Our boilers are engineered to meet the highest standards of performance and reliability, providing efficient and clean energy solutions.

Choosing a reputable manufacturer in India for efficient and reliable palm waste and Napier grass fired boilers is of utmost importance. With our expertise in biomass-fired boilers and a strong focus on customer satisfaction, we are the preferred choice for businesses seeking high-quality boilers.

Our customized solutions cater to specific industry needs and comply with stringent regulations. Whether it’s palm waste boilers or Napier grass fired boilers, our products are designed to optimize fuel combustion, minimize emissions, and ensure operational efficiency.

Efficient and Reliable Palm Waste / Napier Grass Fired Boilers – Made in India

Benefits of using palm waste and Napier grass as biofuels:

Utilizing palm waste and Napier grass as biofuels in boilers offers numerous benefits.

- These biomass fuels are sustainable and renewable, making them environmentally friendly choices.

- Decreasing dependency on fossil fuels and working towards a better future by using agricultural waste items as biofuels, such as palm waste and Napier grass.

- Cost-effective option for enterprises seeking alternative energy sources.

- Widely accessible in India, making them practical and available for various applications.

How palm waste and Napier grass boilers work:

Boilers made from Napier grass and palm trash work on the basis of biomass combustion.

These boilers were created with the particular purpose of burning palm trash and Napier grass effectively while producing steam or hot water for various industrial applications.

The combustion chamber of the boiler receives the biomass fuel, which is then put there to go through a controlled combustion process.

Combustion heat is sent to the boiler’s water or steam circuits, where it can be used for heating, producing electricity, or other industrial purposes.

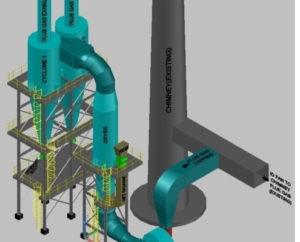

Modern technology offers high combustion efficiency, ideal heat transfer, and little pollutants.

Overview of palm waste / Napier grass fired steam boiler manufacturers in India:

India is home to several reputable palm waste and Napier grass fired steam boiler manufacturers. These manufacturers specialize in designing and producing boilers specifically tailored to efficiently burn palm waste and Napier grass as biofuels.

Their expertise lies in creating boilers with advanced combustion systems, efficient heat transfer surfaces, and robust construction to withstand the challenges associated with biomass combustion.

These manufacturers also offer customized solutions to meet the specific needs of different industries, ensuring optimal performance and reliability.

Key features of the boilers:

When choosing a palm waste boiler manufacturer or Napier grass boiler manufacturer in India, it is important to consider key features that contribute to superior performance and efficiency. These may include:

- Robust construction and high-quality materials to withstand the demands of biomass combustion.

- Advanced combustion systems for efficient and clean combustion, minimizing emissions.

- Efficient heat transfer surfaces to maximize energy efficiency and minimize fuel consumption.

- Flexible design options to accommodate varying palm waste and Napier grass characteristics.

- Comprehensive controls and automation systems for safe and reliable boiler operation.

- Ongoing technical support and maintenance services to ensure optimal performance.

By selecting a reliable palm waste boiler manufacturer or Napier grass boiler manufacturer in India, businesses can benefit from cutting-edge technology, customized solutions, and ongoing support to maximize the potential of palm waste and Napier grass as biofuels.

Application uses and cases

Palm waste and Napier grass fired boilers are used in various industries and applications, including:

a) Palm oil industry:

Palm waste, such as empty fruit bunches, palm kernel shells, and fibers, are abundant byproducts of the palm oil extraction process. These boilers are used to generate steam and power for the production processes in palm oil mills.

b) Biomass power plants:

Palm waste and napier grass can be used as biomass fuels in dedicated power plants. These boilers are made to generate steam at high pressure, which powers steam turbines to produce energy. It is possible to use the generated energy on-site or to feed it to the local power system.

c) Pulp and paper industry:

The boilers can utilize palm waste and napier grass as fuel for steam generation, which is used in various processes in pulp and paper manufacturing, such as pulp production, drying, and bleaching.

d) Textile industry:

Palm waste and napier grass fired boilers can provide steam for textile processing, including dyeing, drying, and printing operations.

e) Food processing industry:

These boilers are suitable for applications in food processing plants, where steam is required for cooking, sterilization, and other processes.

Benefits of using palm waste and napier grass fired boilers in India:

a) Renewable energy source:

Palm waste and napier grass are renewable biomass resources, which helps reduce reliance on fossil fuels and contribute to sustainable energy production.

b) Waste utilization:

By using palm waste as fuel, these boilers enable the efficient utilization of waste materials that would otherwise be discarded or require additional waste management processes.

c) Lower greenhouse gas emissions:

Compared to traditional coal-fired boilers, biomass-fired boilers emit less carbon dioxide, making them a more environmentally responsible option .

d) Cost-effective:

In India, where palm waste and napier grass are readily available, using these biomass fuels can offer cost savings compared to fossil fuel alternatives.

e) Local economic development:

Adopting palm waste and napier grass fired boilers in India supports the development of local industries, creating job opportunities and fostering economic growth.

Comparison with Traditional Boilers:

Comparison of palm waste/Napier grass fired boilers with traditional boilers:

Efficiency:

Palm waste/Napier grass fired boilers can offer comparable or even higher efficiency compared to traditional boilers. They are designed to optimize the combustion process, ensuring maximum heat transfer and energy conversion from the biomass fuel.

Advanced technologies such as fluidized bed combustion and efficient heat recovery systems enhance their overall efficiency. Traditional boilers, especially older models, may have lower efficiency due to outdated designs and less efficient combustion processes.

Reliability:

Boilers that are powered by palm waste or napier grass are built to be incredibly durable and dependable. To make sure they perform well and are durable, they go through rigorous testing and quality control.

To ensure that these boilers run efficiently, manufacturers frequently offer maintenance and technical assistance. Depending on their design, maintenance procedures, and age, conventional boilers can have varying degrees of reliability.

The reliability of older boilers may be impacted since they may be more prone to malfunctions and need more regular maintenance.

Environmental Impact:

When compared to conventional boilers, palm waste/napier grass burned boilers have a much lower environmental impact. Because the carbon dioxide emitted during combustion is equal to the carbon dioxide absorbed by the plants throughout their growth, biomass fuels are regarded as carbon neutral.

Utilising these boilers thereby aids in lowering greenhouse gas emissions and reducing climate change. On the other hand, conventional boilers usually burn fossil fuels like coal, oil, or natural gas, which results in significant emissions of pollutants into the air, including carbon dioxide, which contributes to air pollution and climate change.

Why palm waste/napier grass boilers are better options for sustainable and cost-effective energy solutions?

Sustainability:

Palm waste and napier grass are renewable biomass resources, which makes them sustainable energy options. These fuels are abundantly available, especially in regions like India, where palm oil production is significant.

By using these agricultural waste materials as fuel, palm waste/napier grass boilers contribute to waste management and reduce the environmental impact associated with their disposal.

Moreover, the cultivation of napier grass for energy purposes can be integrated with sustainable land management practices, such as crop rotation and soil enrichment.

Cost-effectiveness:

Palm waste and napier grass might be less expensive than fossil fuels. Because these biomass resources are available close to where they are needed, transportation expenses are reduced, making them a more cost-effective option for generating electricity.

Furthermore, businesses might be able to reduce their dependency on expensive fossil fuels by implementing biomass fuels, which could result in long-term cost benefits.

Government subsidies, tax breaks, and laws supporting renewable energy that boost the use of biomass for power generation could further increase financial viability.

Customization and Support by Uttamenergy:

Uttamenergy provides a range of customization options and comprehensive support services for palm waste/napier grass fired boilers. Their offerings include:

a) Customized Boiler Design:

Uttamenergy understands that each customer may have specific requirements and site conditions. They offer tailored boiler designs to ensure optimal performance and integration with existing systems.

b) Fuel Flexibility:

Uttamenergy’s boilers can be designed to accommodate a variety of biomass fuels, including palm waste and napier They work closely with customers to determine the most suitable fuel options based on availability, quality, and desired energy output.

c) Engineering and Technical Support:

Uttamenergy has a team of experienced engineers and technicians who provide support throughout the project lifecycle.

From initial consultations to installation and commissioning, they ensure seamless integration and operational efficiency.

d) Maintenance and After-sales Service:

Uttamenergy offers maintenance contracts and after-sales support to ensure the long-term performance and reliability of their boilers. Regular inspections, spare parts availability, and troubleshooting assistance are part of their commitment to customer satisfaction.

Assistance in Choosing the Right Boilers:

Uttamenergy assists customers in selecting the most suitable palm waste/napier grass fired boilers based on their specific requirements. They consider factors such as:

a) Fuel Availability:

Uttamenergy assesses the availability and quality of palm waste or napier grass in the customer’s region to determine the feasibility and cost-effectiveness of using these biomass fuels.

b) Energy Demand:

They work closely with customers to understand their energy needs and provide customized solutions that meet the required steam capacity and power generation.

c) Efficiency and Performance:

Uttamenergy evaluates the customer’s operational goals and recommends boilers with the appropriate combustion technology, efficiency levels, and emissions control to ensure optimal

d) Budget Considerations:

We take into account the customer’s budget constraints and offer cost-effective solutions that align with their financial resources.

By considering these factors, Uttamenergy helps customers make informed decisions, ensuring that the selected boilers meet their specific requirements and deliver the desired performance and efficiency.

Why Choose Uttamenergy for Palm Waste/Napier Grass Fired Steam Boilers:

Efficient and Reliable Solutions:

Uttamenergy specializes in designing and manufacturing efficient and reliable palm waste/napier grass fired boilers. Their products are known for their high performance, durability, and adherence to international quality standards.

Expertise and Experience:

With years of industry experience, Uttamenergy has amassed substantial knowledge of biomass combustion technology. Our engineering and technical staff are equipped with the knowledge and know-how to offer technical assistance and creative solutions.

Customer Satisfaction:

Uttamenergy has a strong track record of customer satisfaction. Our focus on understanding customer requirements, providing customized solutions, and offering reliable support services has earned us a reputation for excellence.

Additional Information

In-house developed Reciprocating Servo Grate (RSG) sized elaborately to complement steam boiler design. Fuel is gravity fed at one end of the grate to promote staged and efficient combustion. This silent combustion results in efficient combustion of higher moisture fuels and lesser fly ash carryover.