Vinasse Fired Incineration Boilers: Reliable & Sustainable Energy Solutions in India

At Uttamenergy, we offer a unique and effective solution with our Vinasse Fired Incineration Boilers. These boilers have been designed to address the specific needs of industries, offering a sustainable alternative for their energy requirements.

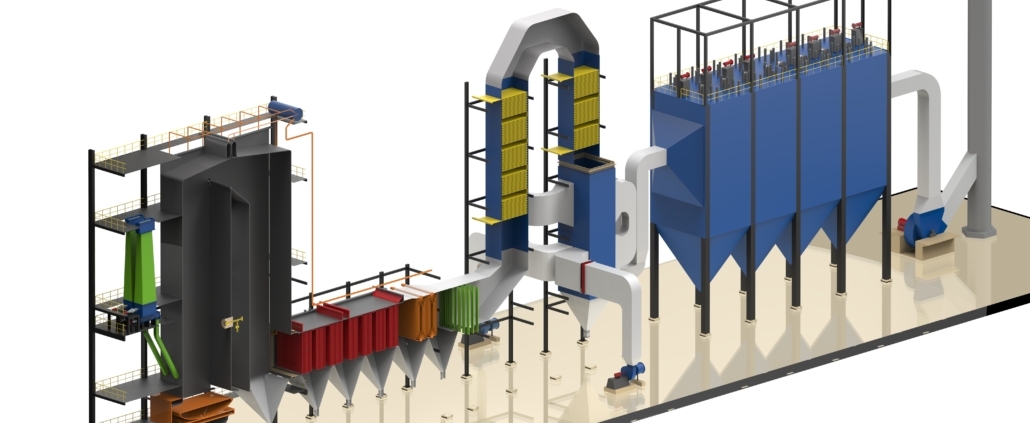

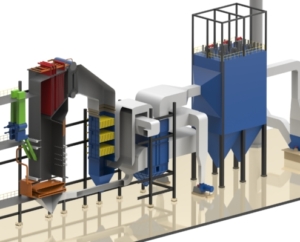

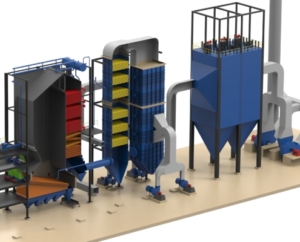

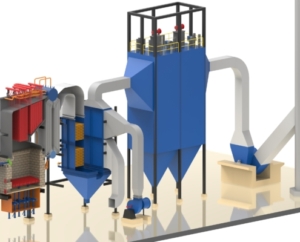

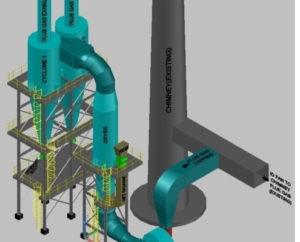

Unique tail end incineration boiler design developed by Uttamenergy exclusively for firing vinasse/slop effluent generated from distillery in combination with support fuels like bagasse, wood chips, rice husk and coal. Careful designing of soot blower mechanism ensures higher availability of boilers.

Uttamenergy dedicated to providing reliable and sustainable energy solutions in India. We understand the pressing issue faced by industries in India in their search for dependable and environmentally friendly energy solutions.

Vinasse Fired Incineration Boilers are not only reliable but also promote sustainability by utilizing vinasse, a byproduct of the distillery industry, as fuel. This innovative approach not only reduces waste but also helps industries reduce their carbon footprint.

Key benefits of our Vinasse Fired Incineration boilers include enhanced energy efficiency, cost savings, and compliance with environmental regulations. We take pride in manufacturing Vinasse Fired Incineration Boilers in a professional manner, ensuring high-quality and reliable products for our customers.

Vinasse Fired Incineration Boilers: Reliable and Sustainable Energy Solutions in India

What is the Vinasse Fired Incineration Boilers

Vinasse Fired Incineration Boilers are innovative and environmentally friendly systems that utilize vinasse as a fuel source for combustion. Vinasse is a byproduct of the distillery industry, typically obtained from the production of alcohol or ethanol.

These boilers work by efficiently burning vinasse, generating high-temperature steam that can be used for various industrial processes or to produce electricity. The combustion process in Vinasse Fired Incineration Boilers is carefully controlled, ensuring optimal energy conversion and minimal emissions.

The use of vinasse as a fuel source offers several significant benefits.

Firstly, it helps industries reduce their environmental impact by providing a sustainable alternative to conventional fossil fuels. Vinasse is a renewable resource that would otherwise be treated as waste, making its utilization in boilers an environmentally responsible choice.

Secondly, using vinasse as a fuel can led to cost savings for industries. As a byproduct, vinasse is often available at a low or even zero cost, reducing fuel expenses significantly. This cost advantage can contribute to the overall profitability and competitiveness of businesses.

Why are Vinasse Fired Incineration Boilers Reliable?

- Vinasse Fired Incineration Boilers are highly reliable energy solutions for industries in India and worldwide.

- Their design and features make them a dependable choice for sustainable and efficient operations.

- Built with robust construction for durability and longevity, they withstand demanding industrial conditions, ensuring a reliable investment for businesses.

- The combustion systems are engineered for efficiency, utilizing advanced technology to optimize the combustion process.

- High energy conversion rates and minimal waste production result from this efficiency, leading to cost savings and reduced environmental impact.

- Distilleries and alcohol production facilities have effectively utilized Vinasse Fired Incineration Boilers to manage vinasse, a byproduct of their operations, achieving enhanced energy efficiency and reduced emissions.

- These boilers offer potential revenue generation through electricity production for industries utilizing them.

- Various sectors like food and beverage, textile manufacturing, and chemical processing have adopted these boilers to optimize energy usage and decrease their carbon footprint.

Why are Vinasse Fired Incineration Boilers Sustainable?

- Vinasse Fired Incineration Boilers offer a sustainable energy solution with several environmental and economic benefits.

- Environmental benefits include the reduction of greenhouse gas emissions by utilizing vinasse, a byproduct of industries like distilleries, as a fuel source.

- These boilers help minimize waste and promote a circular economy by repurposing otherwise unused resources, reducing the carbon footprint and preventing unsustainable disposal of byproducts.

- Economic advantages come from significant reductions in energy costs for industries adopting these sustainable energy solutions.

- The efficient combustion systems ensure optimal fuel utilization, leading to lower fuel consumption and operational expenses.

- Investing in sustainable technologies like Vinasse Fired Incineration Boilers showcases a commitment to corporate social responsibility (CSR).

- Companies prioritizing sustainability and environmental stewardship can enhance their brand reputation, attract eco-conscious customers, and comply with stringent regulations.

- Manufactured in India, these boilers align with the country’s focus on sustainable development and renewable energy sources.

- Designed and built by experts, they ensure high-quality and reliable performance for industries in India and beyond.

- Choosing Vinasse Fired Incineration Boilers allows industries to contribute to a greener future, reduce environmental impact, achieve cost savings, and enhance overall sustainability efforts.

Vinasse Fired Incineration Boilers: Benefiting Industries in India

Distillery Industry Benefits:

- Vinasse Fired Incineration Boilers provide a solution for the distillery industry, effectively utilizing vinasse as a fuel source, a substantial byproduct of distilleries’ operations.

- Implementing these boilers assists distilleries in managing waste while generating clean energy, reducing reliance on fossil fuels and lessening their environmental impact.

Paper and Pulp Industry Advantages:

- Vinasse Fired Incineration Boilers offer substantial heat and energy required in the paper and pulp industry’s processes.

- Utilizing these boilers allows paper and pulp manufacturers to leverage vinasse as a sustainable energy source, leading to cost savings, operational efficiency, and reduced carbon footprint.

Impact on India’s Carbon Footprint:

- Vinasse Fired Incineration Boilers across various industries have the potential to significantly reduce the country’s carbon footprint.

- Industries using vinasse as a renewable fuel source can lower greenhouse gas emissions, aligning with India’s sustainability goals for sustainable development and renewable energy.

Tailored for Indian Industries:

- Manufactured in India, these boilers are specifically designed to meet the needs of the country’s industries, ensuring construction, efficiency, and reliable performance tailored to local requirements.

Dual Benefits for Indian Industries:

- Adoption of Vinasse Fired Incineration Boilers in Indian industries facilitates reduced environmental impact and enhanced operational efficiency, contributing to India’s journey towards a greener and more sustainable future.